I design and manage production of all enamel pins for my store from concept sketches to final approvals and QA once they arrive. I like to emphasize the materiality and inherent properties of all mediums I work with, leading me to seek new ways to push the limits of what enamel pin designs are possible.

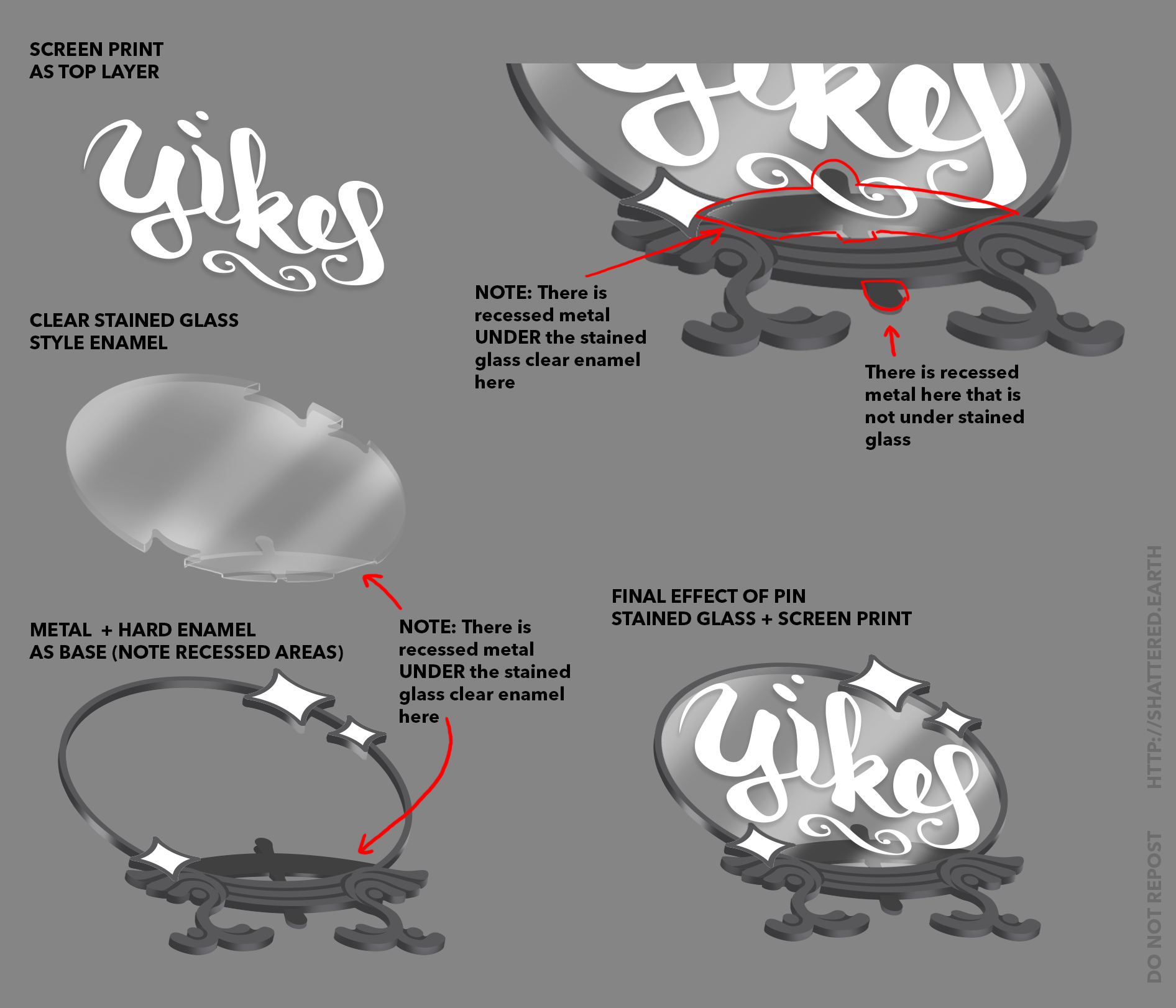

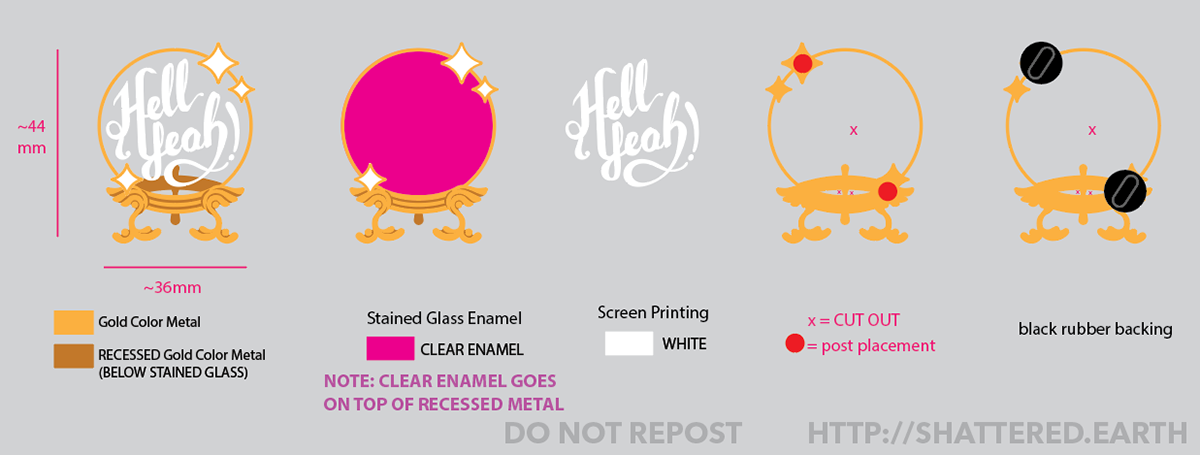

I communicate directly with manufacturers and provide detailed spec sheets and diagrams to make sure detailed and complex designs are properly executed.

Below is an example of the process overview from sketch to final specs and diagrams that would accompany an order to make sure there is no miscommunication. Complex designs have many working parts that must be carefully depicted so both parties are always on the same page.

I make sure my diagrams can be understood by any member of staff who receives my files whether they are the sales associates or the workers on the factory floor.

This saves time spent on revisions and provides a great record to refer to if any problems arise.

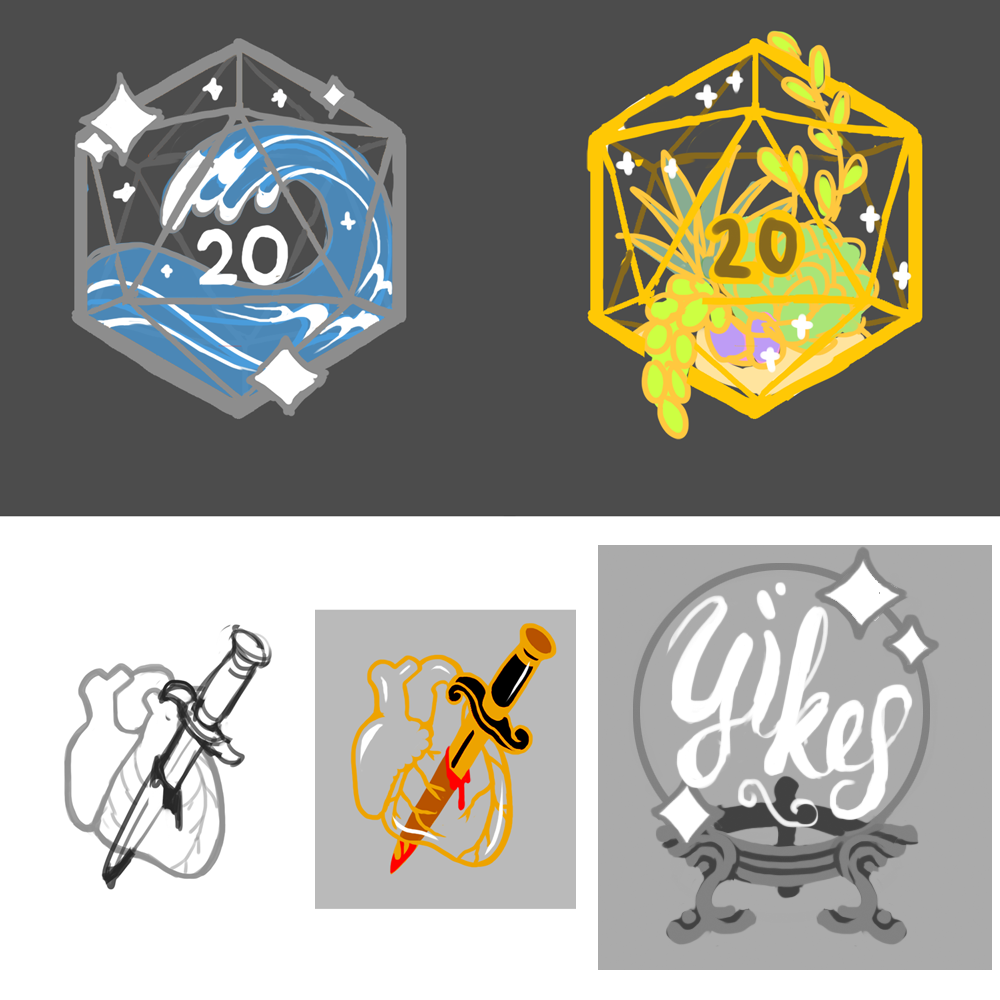

Below is another example of an enamel pin based off of a washi tape design I created earlier.

I was able to repurpose some of the concept work and converted points of the design to work better as an enamel pin. This allowed me to showcase blocks of solid metal as well as techniques unique to enamel pins such as pearlescent swirled enamel.

Special consideration had to be paid for the silhouette, as protruding too far with thin lines creates break hazards and heightens production risk, but just enough creates a unique look.

Additional enamel pin designs below, all of which I designed and took into production with manufacturers directly.